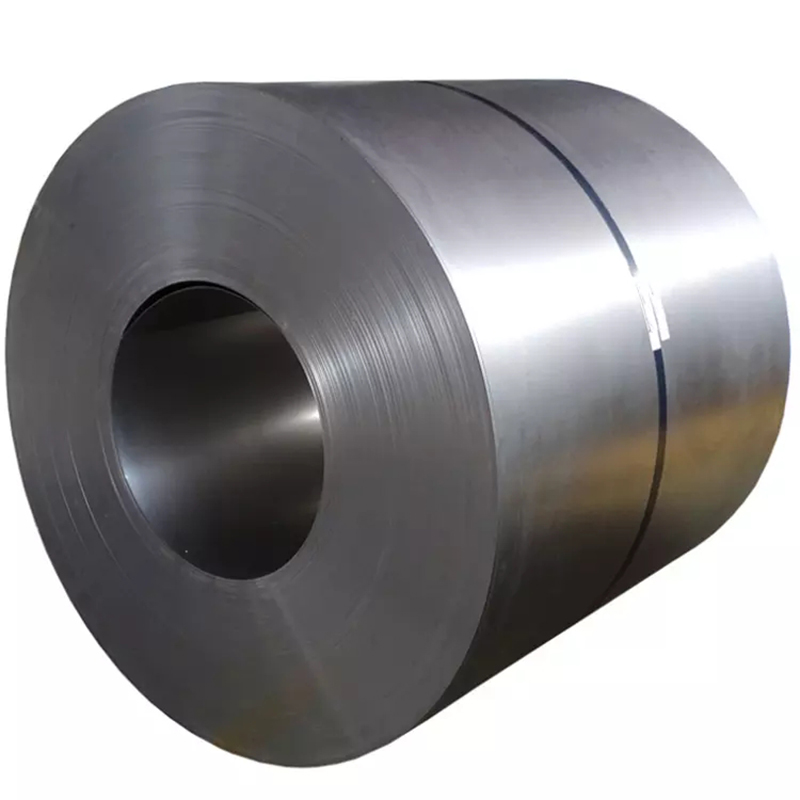

The 2011 aluminum coil is a high-strength alloy specifically designed for precision machining applications. Known for its exceptional machinability, this alloy is part of the 2000 series, which is characterized by its copper content for enhanced strength and durability. Whether you need reliable material for aerospace, automotive, or industrial use, the 2011 aluminum coil delivers outstanding performance and consistent results.

Key Features of 2011 Aluminum Coil

The 2011 aluminum coil offers several distinctive properties that make it a preferred choice for demanding applications:

Superior Machinability: Renowned as one of the most machinable aluminum alloys, it enables faster and more precise fabrication.

High Strength: Enhanced with copper, the alloy offers excellent tensile strength and durability.

Corrosion Resistance: Provides good resistance to atmospheric conditions, ensuring long-term performance.

Thermal and Electrical Conductivity: Performs well in applications requiring efficient energy transfer.

Surface Finish: Capable of achieving smooth and polished surfaces for aesthetic or functional purposes.

Lightweight: Retains aluminum's lightweight properties while offering superior mechanical strength.

Applications of 2011 Aluminum Coil

The versatility of 2011 aluminum coil makes it suitable for a variety of industries and applications:

Aerospace: Used in precision components such as fittings, fasteners, and control systems.

Automotive: Ideal for engine parts, connectors, and intricate components requiring superior machinability.

Industrial Equipment: Widely used in manufacturing tools, jigs, and machinery requiring tight tolerances.

Electronics: Common in parts requiring both strength and excellent conductivity.

Custom Components: Perfect for parts requiring custom fabrication with high precision and surface finish.

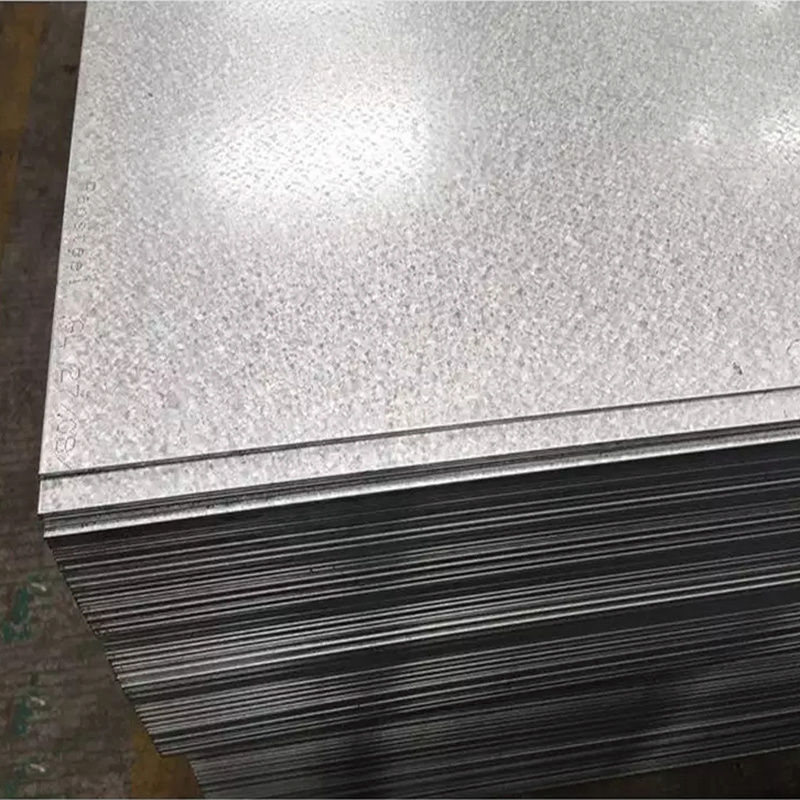

Technical Specifications

| Property | Details |

| Chemical Composition | Copper (4.0-5.0%), Aluminum (Balance) |

| Density | 2.85 g/cm³ |

| Tensile Strength | 310-365 MPa |

| Machinability Rating | Excellent (Rated 100% for machining) |

| Corrosion Resistance | Good for non-marine environments |

| Thermal Conductivity | High |

Benefits of Choosing 2011 Aluminum Coil

Opting for 2011 aluminum coil provides several benefits:

Increased Efficiency: Its machinability reduces production time, minimizing costs and maximizing output.Reliable Performance: High strength and durability ensure reliable performance in demanding environments.Customizable Fabrication: Perfect for intricate designs and tight tolerances.Lightweight Advantage: Ideal for industries where weight reduction is critical without compromising strength.

Why Choose Us?

At Gangshun Metal Products, we are committed to providing high-quality aluminum products tailored to your exact needs. Here’s why we are the trusted choice for 2011 aluminum coils:

Premium Quality Standards: All our products meet stringent industry requirements for strength, durability, and performance.

Customization Options: Available in various sizes, thicknesses, and finishes to meet your specific project needs.

Competitive Pricing: Enjoy top-quality materials at affordable prices.

Reliable Delivery: We ensure timely and secure delivery to keep your projects on track.

Expert Support: Our team of experts is here to provide guidance and support for all your aluminum coil requirements.

The 2011 aluminum coil is the ultimate choice for precision machining applications, offering unmatched machinability, high strength, and excellent durability. It’s a reliable material for industries that demand precision and consistent performance, such as aerospace, automotive, and industrial manufacturing.

Contact us today to learn more about our 2011 aluminum coils and find the perfect solution for your project. Let us help you achieve the quality and precision your work deserves!