Composition and Characteristics

The impressive performance of 6063 aluminum coil is due to its carefully balanced chemical composition, which typically includes:

Aluminum (Al):Balance

Magnesium (Mg):0.45-0.9%

Silicon (Si):0.2-0.6%

Iron (Fe):0.35% max

Copper (Cu):0.1% max

Manganese (Mn):0.1% max

Chromium (Cr):0.1% max

Zinc (Zn):0.1% max

Titanium (Ti):0.1% max

This composition gives 6063 aluminum its key properties:

Good Corrosion Resistance:6063 aluminum offers excellent resistance to corrosion, making it suitable for both indoor and outdoor applications, including those exposed to the elements.

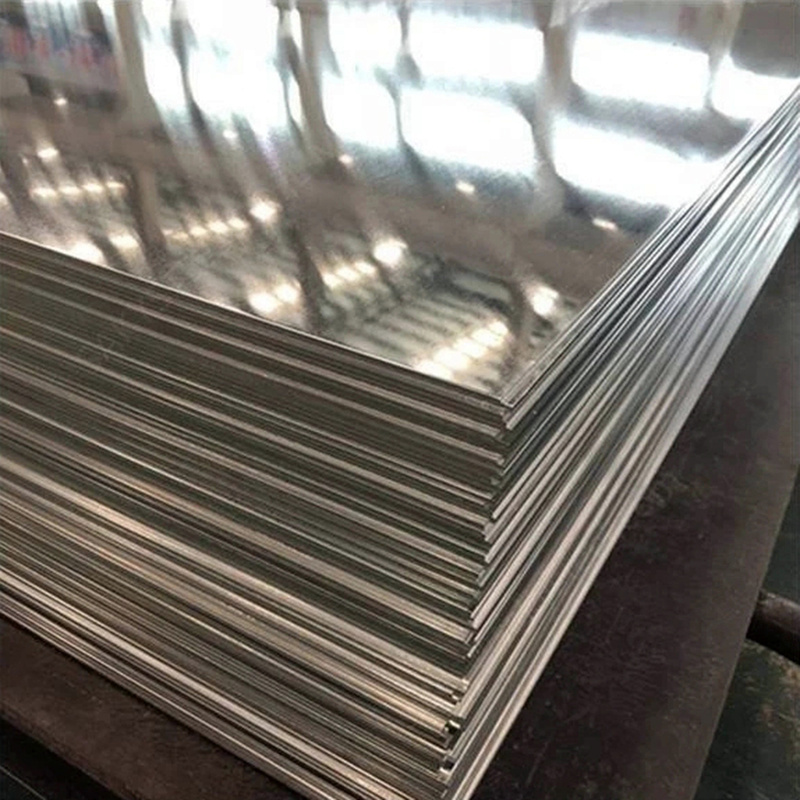

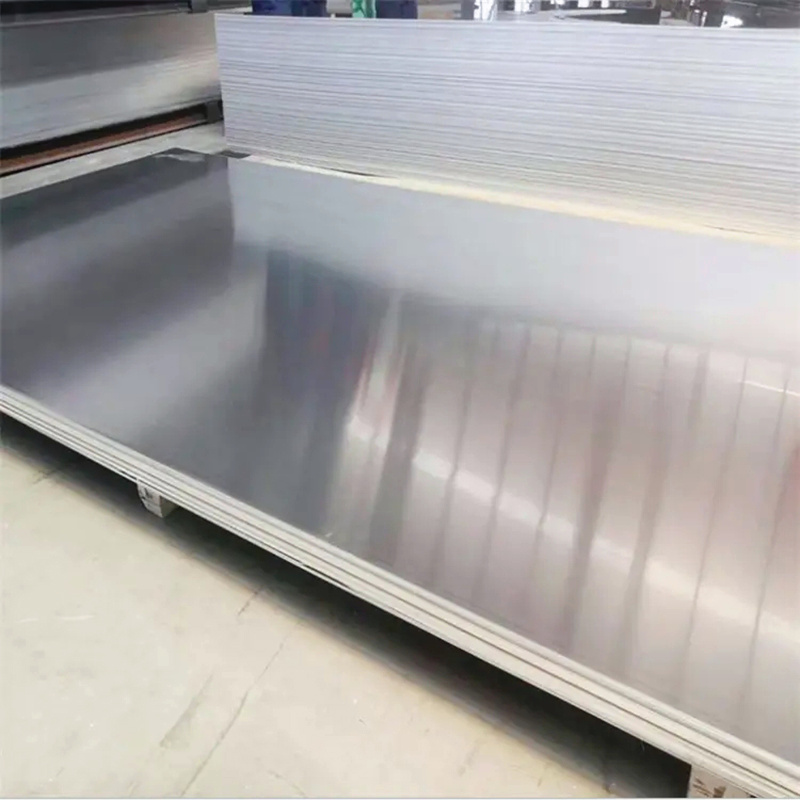

High Formability:The alloy’s good formability allows it to be easily extruded, rolled, and shaped into complex profiles and configurations without losing its mechanical integrity. This makes 6063 aluminum coil particularly well-suited for architectural applications where intricate designs are required.

Smooth Surface Finish:One of the standout features of 6063 aluminum is its ability to achieve a smooth, high-quality surface finish, which can be anodized to enhance its appearance and provide additional protection against corrosion.

Moderate Strength:While not as strong as some other aluminum alloys, 6063 offers sufficient strength for many structural and decorative applications, especially where aesthetics and corrosion resistance are prioritized.

Key Properties

6063 aluminum coil is valued for its range of properties that make it an excellent material for various applications:

Corrosion Resistance:The alloy’s resistance to corrosion in different environments, including exposure to moisture and chemicals, makes it suitable for both outdoor and indoor applications.

Aesthetic Appeal:6063 aluminum’s ability to achieve a smooth surface finish makes it ideal for applications where appearance is important, such as in architectural and decorative projects.

Versatility:The combination of strength, formability, and surface finish allows 6063 aluminum to be used in a wide variety of applications, from structural components to consumer products.

Weldability:6063 aluminum’s good weldability makes it easy to join with other materials, providing flexibility in design and fabrication.

Applications of 6063 Aluminum Coil

6063 aluminum coil is used across a wide range of industries where its combination of corrosion resistance, aesthetic appeal, and formability provides significant advantages. Common applications include:

Architectural Applications:6063 aluminum is widely used in the construction industry for applications such as window frames, door frames, roofing, and curtain walls, where its corrosion resistance and smooth finish are highly valued.

Automotive Industry:The alloy is used in the automotive sector for trim, body panels, and other components where a smooth finish and corrosion resistance are important for both performance and appearance.

Furniture and Consumer Goods:6063 aluminum is often used in the manufacturing of furniture, appliances, and other consumer goods where a combination of strength, lightweight, and aesthetic appeal are essential.

Electrical Applications:The alloy’s good conductivity and corrosion resistance make it suitable for use in electrical components, such as heat sinks and radiators.

Marine Applications:Due to its resistance to saltwater corrosion, 6063 aluminum is also used in marine environments for components such as boat railings, hardware, and fittings.

Advantages of Choosing 6063 Aluminum Coil

When selecting a material for your project, 6063 aluminum coil offers several compelling advantages:

Corrosion Resistance:6063 aluminum’s excellent resistance to corrosion makes it ideal for use in environments where exposure to moisture, chemicals, and the elements is common.

Aesthetic Flexibility:The alloy’s ability to achieve a smooth, high-quality finish allows for customization and enhancement through anodizing or other surface treatments, making it suitable for decorative applications.

Formability:The alloy’s good formability allows for the easy fabrication of complex shapes and designs, making it suitable for a wide range of applications.

Cost-Effective:6063 aluminum provides a cost-effective solution without sacrificing performance, making it an economical choice for both large-scale projects and custom applications.

Conclusion

6063 aluminum coil is a versatile and durable material that offers an excellent balance of corrosion resistance, aesthetic appeal, and formability. Whether you are working in the architectural, automotive, or marine industries, 6063 aluminum coil provides the reliability and performance you need to achieve the best results. Explore our selection of 6063 aluminum coils today and find the perfect solution for your next project.